Heat sink manufacturing technologies

Heatsinks are an important component in electronic devices to dissipate heat and extend the life of the devices. In recent years, various technologies have been developed to improve the efficiency of heat sinks. These include new manufacturing methods and innovative materials that enable better heat sink designs. These technologies help optimize heat dissipation and distribution and lower the operating temperatures of electronic devices, resulting in better performance, reliability and longer device life.

Heat sink technologies

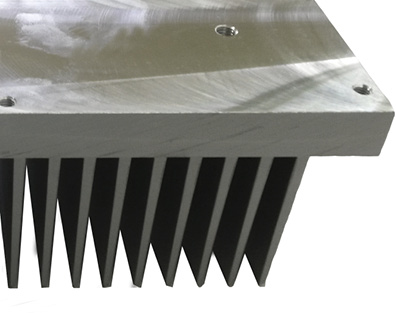

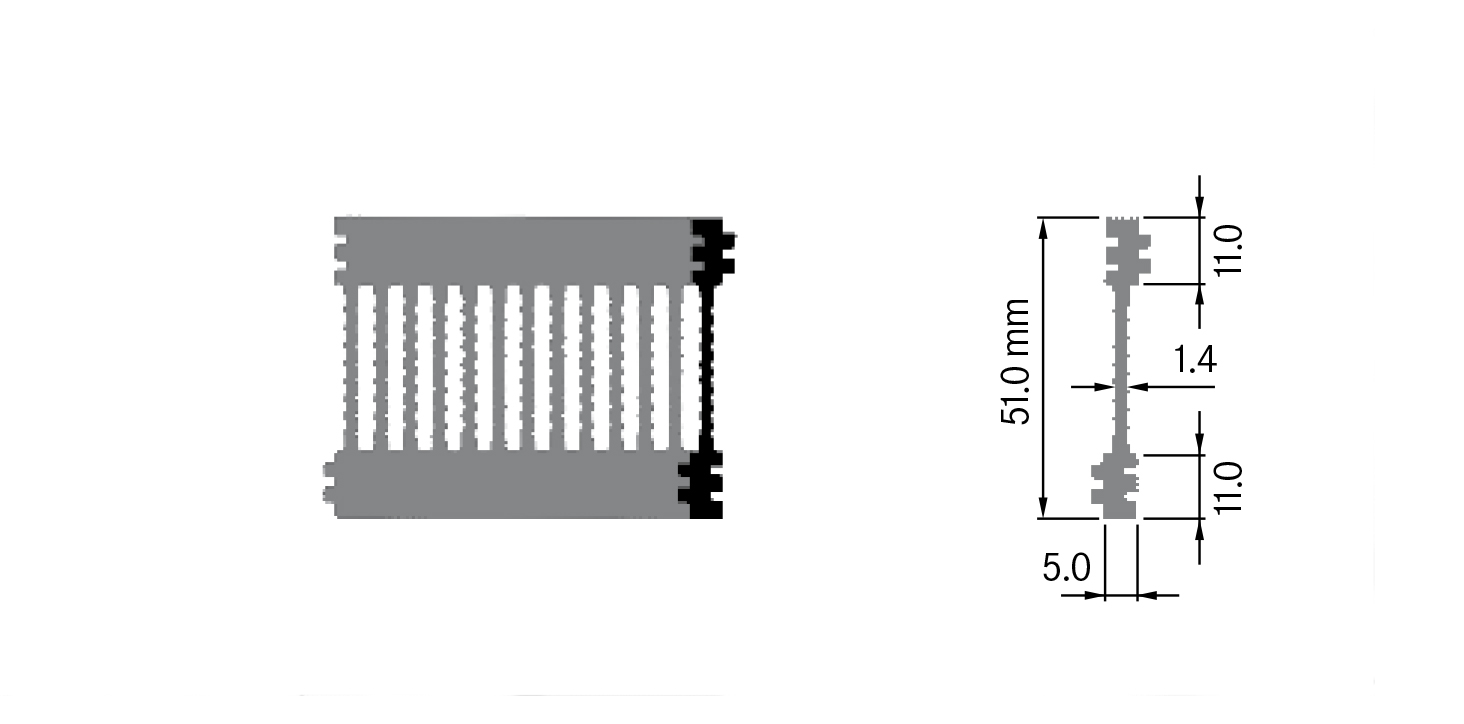

Friction Stir Welding (Friction Stir Welding)

Friction stir welding is assigned to the pressure welding processes. In friction stir welding, metals are joined below the melting point. This creates pressure- and vacuum-tight joints without pores and cracks. The technology is mainly used in railroad engineering.

Main features

Design

- Very wide heat sink designs possible with improved fin spacing

Material

- No structural changes

- Without filler materials and large manufacturing losses

Technology

- Seamless joining of two aluminum parts

- Hot forming process below the melting point, fine-grained microstructure